How to Improve MTTR and MTBF: Ways to Boost Reliability

In any operational setting, from data centers to factories to cloud services, minimizing downtime and boosting system reliability are essential for success. Even a short disruption can lead to reduced productivity, delayed output, and unhappy customers.

To manage these risks, organizations track two key metrics: Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF). These key performance indicators reveal how fast you recover from issues and how often failures happen.

A low MTTR and high MTBF usually mean your systems are running smoothly, your team is well-prepared, and your processes are working. Improving both can lead to better uptime, lower costs, and stronger customer satisfaction.

In this guide, we'll explore how better maintenance, smart monitoring, and team training can improve these metrics and how to apply them in real-world scenarios.

Understanding MTTR and MTBF: What They Mean and Why They Matter

Before improving your maintenance strategy, it's important to understand what MTTR and MTBF actually mean. These two incident management metrics are often used together to measure how reliable a system is and how quickly your team can respond when something goes wrong. Both play a big role in planning, tracking, and improving your overall operational efficiency.

They are also key to reducing risk and avoiding unplanned downtime.

What MTTR Means and How It’s Used

MTTR stands for Mean Time To Repair. It is a common way to measure how long it takes to fix something after a system failure. The metric helps teams understand how quickly they can restore full operations.

To calculate MTTR, you divide the total time spent on repairs by the total number of failures. For example, if a system failed five times last month and the total repair time was 10 hours, the MTTR would be 2 hours.

MTTR measures more than just the time taken to make a repair. It also reflects how well your team responds to issues. A shorter MTTR often means better incident response, faster decision-making, and smoother processes.

Think of it this way. If your website crashes or a machine in your shop stops working, the MTTR is the average time it takes to troubleshoot and fix the issue. The faster the recovery, the better your chances of keeping your productivity and customer satisfaction high.

What MTBF Means and Why It’s Crucial for Reliability

MTBF stands for Mean Time Between Failures. It tells you how often a system or machine breaks down. This metric is used to evaluate how reliable a piece of equipment is over time.

To calculate MTBF, take the total operational time and divide it by the number of failures. For example, if a machine ran for 1,000 hours and failed 4 times, the MTBF would be 250 hours. That means, on average, the system works for 250 hours before failing.

MTBF indicates how well a system performs without interruption. A higher MTBF usually means better design, proper maintenance, and fewer disruptions. It also helps you plan for replacements, schedule preventive maintenance, and extend the lifespan of a system.

It’s helpful to compare MTBF with MTTF, which stands for mean time to failure. MTTF is used for products that cannot be repaired, such as a disposable sensor or a single-use battery. In contrast, MTBF is used for systems that can be fixed after they break.

Imagine you’re managing a fleet of delivery vehicles. If one truck usually runs 20 days before it needs repair, its MTBF is 20 days. Increasing that number would mean fewer breakdowns and more reliable deliveries.

How to Reduce MTTR for Faster Recovery

If you want to improve your system’s ability to recover after a failure, start by focusing on MTTR. Short for mean time to repair, this metric tells you how fast your team can fix a problem and get everything back up and running. Reducing MTTR helps you minimize downtime, improve service quality, and boost overall operational efficiency.

Below are three key strategies to reduce your MTTR, from early detection to faster response.

1. Improve Issue Detection with Real-Time Monitoring

In any SaaS environment, fast response is key. One of the core SaaS monitoring best practices is setting up real-time monitoring to catch issues the moment they occur. You can’t fix a problem if you don’t know it exists. That’s why early detection is critical in reducing MTTR. The sooner your team is alerted, the quicker the issue can be resolved.

To improve detection:

Use real-time monitoring tools to watch for system failures as they happen.

Set up alerts that go to the right teams without delay. For example, if a third-party service goes down, a platform like IsDown can notify you instantly.

Avoid alert overload by setting severity-based notifications. This helps your team focus only on the most urgent issues.

Early alerts help quickly identify and address issues, saving valuable time and avoiding larger disruptions.

2. Streamline Response with Clear Processes and Communication

Once an alert is received, your team should know exactly what to do next. A slow or unclear process can increase the time spent on repairs, which hurts your performance.

To streamline your repair process:

Create standard operating procedures (SOPs) for different types of incidents.

Define clear escalation paths, so responsibility passes smoothly if the first line of response can’t solve it.

Use collaboration tools for faster updates and better team coordination.

Automate repeatable actions where possible, like restarting a service or running diagnostics.

By removing delays and confusion, you can cut the time it takes to repair and recover more efficiently.

3. Train Teams and Cross-Train Roles

No matter how good your tools are, your team needs the right skills to use them. Well-trained staff can diagnose and fix issues faster, which helps lower your MTTR.

Training strategies that work:

Offer regular skill-building sessions to reduce errors and improve speed.

Cross-train team members so they can cover for each other during outages or off-hours.

Keep a record of past incidents, repairs, and lessons learned to strengthen your team’s ability to respond in future situations.

This approach builds a proactive team that is better prepared to reduce disruptions and respond under pressure.

How to Increase MTBF for More Reliable Systems

Improving MTBF, or Mean Time Between Failures, is all about making your systems more dependable. A higher MTBF means your equipment or processes run longer before needing repairs. When systems fail less often, you reduce the risk of interruptions, lower maintenance costs, and improve your overall system reliability.

Here are three strategies to help you extend the time between failures and build more reliable operations.

1. Apply Preventive and Predictive Maintenance

One of the most effective ways to increase MTBF is to stop problems before they start. This means using both preventive and predictive maintenance strategies.

Preventive maintenance involves performing regular service tasks based on time or usage. This includes inspections, cleaning, lubrication, and replacing worn parts before they cause a failure.

Predictive maintenance goes a step further. It relies on condition monitoring tools like sensors, vibration analysis, and thermal imaging to detect early warning signs. These systems allow teams to take action based on real-time data.

By fixing issues early, you reduce the likelihood of system failure and help your equipment last longer. Acting before a breakdown occurs can significantly improve system reliability and reduce unexpected disruptions.

2. Use Better Parts and Improve Design Quality

Sometimes, the reason for frequent failures comes down to poor materials or weak design. Low-quality parts can wear out quickly, and design flaws may cause repeated stress or breakdowns.

To avoid this:

Use high-grade components that meet or exceed industry standards.

Reassess systems or machines that fail often and look for opportunities to optimize the design.

Work with vendors or engineers to identify weak points and correct them.

Investing in quality materials and thoughtful design helps raise MTBF and extends the lifespan of a system.

3. Conduct Root Cause Analysis (RCA) After Every Failure

When failures do happen, the goal should be to learn from them. Root cause analysis helps uncover the reason behind an issue, not just the symptom. This is key to avoiding repeat problems.

Common approaches include:

The “5 Whys” method, which asks why a problem occurred until the root cause is clear.

Log analysis or automated diagnostics that point to specific failure points in the system.

Once the issue is identified:

Document your findings clearly.

Share them with the team.

Update your maintenance practices to prevent the same issue in the future.

This cycle of learning and improving is central to reducing failures of a system and building a more proactive maintenance culture.

Using Metrics Together: MTTR vs. MTBF

While MTTR and MTBF are often viewed separately, using them together gives you a much better understanding of how your systems perform. These two metrics work hand in hand to show both how often things break and how fast your team can fix them.

MTBF, or Mean Time Between Failures, focuses on system reliability. A higher MTBF means your equipment breaks down less often. On the other hand, MTTR, or Mean Time to Repair, indicates the average time required to repair something once it fails. A lower MTTR reflects a faster incident response and repair process.

If you only track one and ignore the other, you may miss what’s really happening in your system.

Example:

System A: Breaks down every 2 days but takes only 30 minutes to fix.

System B: Breaks down only once every 15 days, but it takes 6 hours to repair.

At first glance, System A seems better because it's fixed quickly. But the frequent failures cause more downtime in the long run. System B has a higher MTBF, which means fewer interruptions, even though it has a slightly longer repair time.

This comparison shows why you need both MTTR and MTBF to make informed decisions about what’s working and what needs improvement.

Calculating System Availability

You can also combine MTTR and MTBF to calculate system availability, which measures how often your system is ready for use.

The formula is:

Availability = MTBF ÷ (MTBF + MTTR)

For example, if a system has an MTBF of 100 hours and an MTTR of 4 hours:

Availability = 100 ÷ (100 + 4) = 100 ÷ 104 = 0.9615 or 96.15%

This means the system is available and operational over 96% of the time. Tracking this number can help you set goals, measure improvements, and align your maintenance strategies.

Tools and Technologies That Help Improve MTTR and MTBF

Improving MTTR and MTBF doesn’t have to rely on manual tracking and guesswork. With the right tools, your team can detect problems faster, respond more efficiently, and reduce the chances of repeated failures. Modern platforms offer features like real-time alerts, system monitoring, historical logs, and performance analysis, making it easier to monitor, manage, and improve these two important metrics.

Use Monitoring and Alerting Tools

To reduce downtime and improve response times, teams need real-time visibility into system health. Monitoring tools help you catch issues as soon as they happen, and automated alerts make sure the right people are notified immediately.

Helpful tools include:

Cloud monitoring platforms that track the health of online services and trigger alerts when something goes wrong.

Uptime tracking software that measures system availability over time.

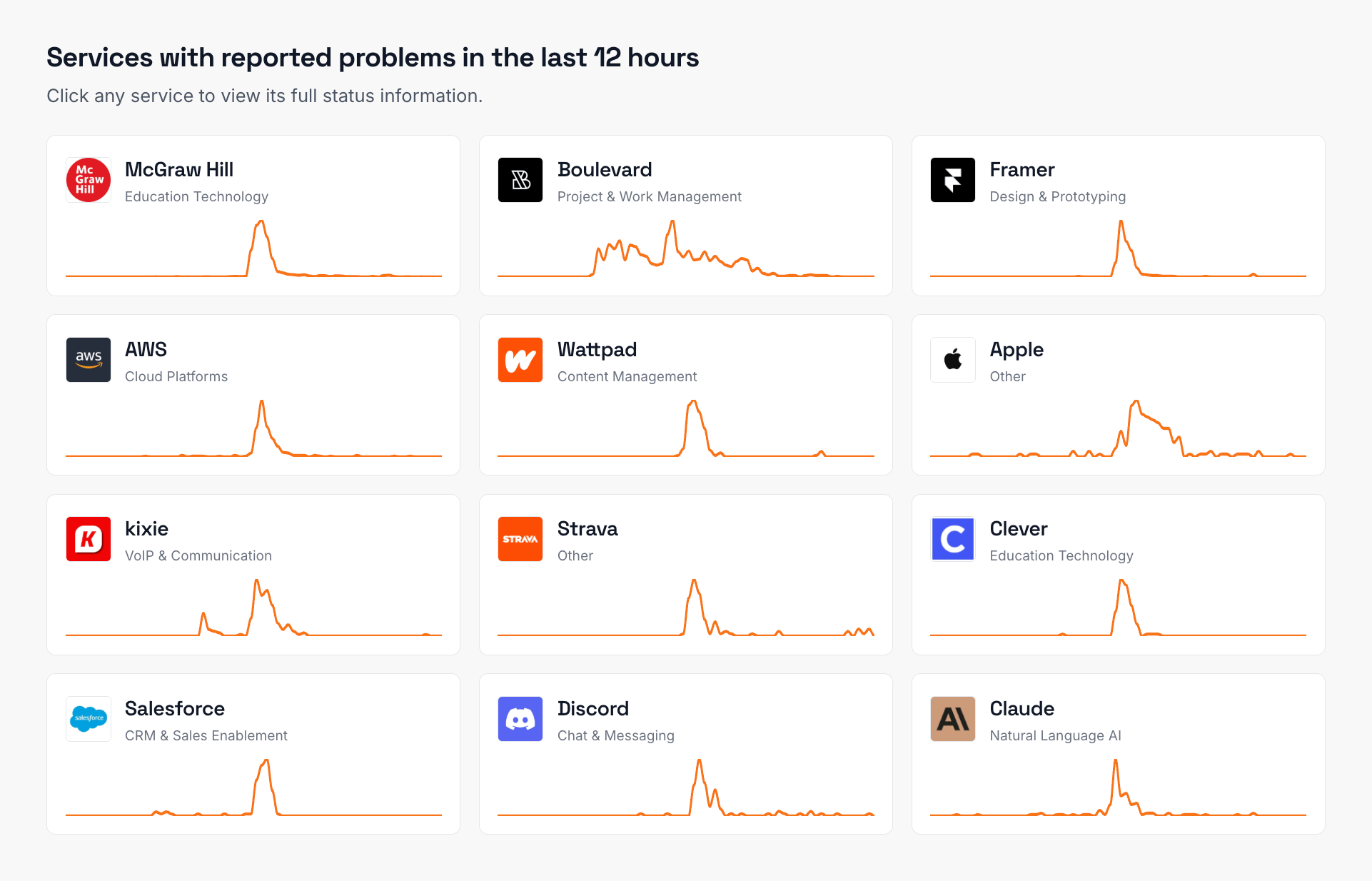

Vendor monitoring tools like IsDown, which alert teams about outages in third-party services that may affect internal operations.

CMMS (Computerized Maintenance Management Systems) and EAM (Enterprise Asset Management) systems help manage internal assets and schedule preventive maintenance tasks.

These tools play a key role in monitoring MTTR, flagging performance drops, and preventing avoidable failures.

Use Analytics to Track Trends and Optimize Response

It’s not just about spotting a problem once; it’s also about recognizing patterns and learning from the past. This is where data-driven analytics can help your team make informed decisions.

Use these tools to:

Review historical incident logs and alert histories to spot weak points in your infrastructure or vendor relationships.

Track MTTR and MTBF over time to see whether your process improvements are working.

Build custom dashboards and reports that give a visual overview of system health, failures, and progress.

Run incident reviews that help your team identify areas for improvement in workflows, communication, or detection accuracy.

When teams consistently review data, they’re better equipped to plan, respond, and improve long-term.

Conclusion: Improve System Reliability with MTTR and MTBF

Reducing MTTR and increasing MTBF are two of the most effective ways to improve overall system performance. When systems recover faster and fail less often, you gain higher uptime, better system reliability, and fewer disruptions to your operations.

Throughout this guide, we explored how these two metrics work together and why it's important to track both. We also covered practical strategies like early detection, preventive maintenance, better team training, and using data to improve decision-making.

To succeed, teams need the right combination of tools, processes, and people. That means investing in monitoring platforms, creating clear workflows, and building a team that’s skilled, prepared, and proactive.

If your company relies on cloud services, external vendors can affect your MTTR and MTBF, too. This is where a status page aggregator like IsDown adds value by monitoring over 4,400 vendors and delivering real-time alerts during outages.

Frequently Asked Questions

What Is the KPI for MTTR?

The MTTR metric is a key performance indicator (KPI) that measures how quickly systems recover after failure. It shows the effectiveness of the repair process and is commonly used to evaluate reliability in incident management.

What Happens When You Increase MTBF?

When MTBF goes up, systems fail less often. A higher MTBF indicates better design, fewer disruptions, and longer-lasting equipment. This directly improves incident management and reduces repair frequency.

What Causes A High MTTR?

A high MTTR may happen when teams don’t have the tools, training, or clear processes needed to respond quickly. This affects the effectiveness of the repair process and slows down incident management.

How To Reduce MTTR In Incident Management?

To reduce MTTR, set up real-time alerts, define clear workflows, and implement team training. These steps help reduce MTTR by improving your incident management response and repair speed.

Nuno Tomas

Founder of IsDown

Nuno Tomas

Founder of IsDown

The Status Page Aggregator with Early Outage Detection

Unified vendor dashboard

Early Outage Detection

Stop the Support Flood

Related articles

Never again lose time looking in the wrong place

14-day free trial · No credit card required · No code required